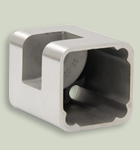

Precision casting –

advantages that can be counted on

Parts that are manufactured in precision casting according to the lost-wax casting process run through a complex process with many manual stages of work. They excel through low tolerances and are a real alternative as well as an economical one to forging most of all, according to the material and surface treatment. We are therefore able to manufacture parts by means of precision casting, which satisfy the highest thermal and mechanical loadings. Some of the materials used are:

Case-hardened steels: GS-16CrMo 4

Hard alloys: G-X125 CoCrW 63 27

Nitriding steels: GS-31 CrMoV 9

Stainless steels: G-X 6 CrNi 18 9

Tempering steels: G-X 4 CrNiCuNb 16 4

High-temperature steels: G-X20 CrCoMo12 2

High-tensile steels: G-X 2 NiCoMo 18 9 5

Non-ferrous metals can also be processed in the precision-casting process of course.

The advantages

- The greatest possible constructional freedom.

Designs can be realized with precision casting that are unachievable with other manufacturing processes or can only be achieved at an extra, high, manufacturing cost (e.g., round thread, gear cutting, lettering).

- Integration of components

Several constructional elements can be integrated into one component and cast in one piece: that saves machining time and assembly time subsequently, as well as the investments in machines and equipment which would be required for this purpose.

- No finishing by means of metal cutting

The particularly low tolerances and high dimensional accuracy with precision casting usually obviate any finishing by means of metal cutting. The parts can be annealed (quenched and tempered) supplementarily, in order to increase their strength.

- Low manufacturing costs

Constructions that are suitable for precision casting and a free choice of materials help to reduce the manufacturing costs. In particular, complex designs as well as high thermal and mechanical loading capacity can clearly be achieved by precision casting more economically than by other casting processes in most cases.

Green and yellow waxes

The lost-wax process with lost green or yellow wax is often recommended for manufacturing large, complex, (stainless) steel cast parts. The various individual components are preassembled and then cast while doing so.

Its advantage is that the parts are even more precise and have a smooth surface. The parts can also be improved (electropolished or trovalized). No further machining is required in most cases.

Our foundry manufactures the parts in all conventional casting materials according to DIN and international standards.

- Cast parts manufactured in the process with green wax (very precise cast parts: each piece weighs between 5 g. and 20 kg.) e.g., for highly sensitive use in the foodstuffs industry, or as parts for operating tables or as parts for sensory equipment.

- Cast parts manufactured in the process with yellow wax (precise cast part: each piece weighs between 50 g. and 100 kg) e.g., for use as automotive parts or in constructing electric motors